|

| Andrew offloads kegs |

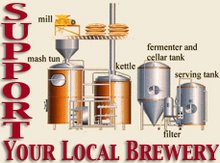

An annoying late-winter snow fell as Bob Olson and Andrew Maiorana rolled into High Point Brewing last Saturday with a load of empty half barrels, sixtels and 180 empty case boxes stacked five high in the rear of a box truck.

After backing up to a loading bay, the two made quick work of their cargo, dropping off the empty kegs for a recharge at High Point, the Jersey craft brewery known for its flight of Ramstein beers.

Bob and Andrew hired the Butler brewery to make their Bolero Snort beers while they scout a location for their own brewery and raise the money to pay for it.

"It's fun trying to juggle the inventory, having two brands and only one tank to put it in," says Bob, standing far inside the brewery, beside a pallet now stacked with the empty case boxes.

Born from a 2010 partnership, Bolero Snort began brewing a High Point back in January, putting the beer in a fermenter installed to facilitate the contract brewing.

It's been about a month since Bolero Snort hit New Jersey's craft beer taps with a sessionable amber lager, Ragin' Bull (5% ABV), and the style-flouting, black IPA-cum-hoppy black lager, Blackhorn (6.5% ABV). The beers were initially previewed around mid-February, then were officially unveiled at a series of launch events across pockets of North Jersey that Bolero Snort has staked out for its distribution.

|

| Case boxes on the truck |

|

| Bob with a case box stack |

This week, Bolero takes another step in the Garden State craft beer scene, with an inaugural bottling run of Blackhorn that will give the Bergen County company a presence in the take-home beer market to backstop the draft business that Bob, a construction consultant, and Andrew, a CPA, have been working in the margins of their day jobs.

The two took some time to talk about life up to now in the craft beer business and where they hope to go.

BSL: You launched at the end of February. How did things go with the rollout of Ragin' Bull and Blackhorn?

BO: It didn't kill us (laughs). It was a lot of fun. Turnout was just as good, if not better, than we expected. Each of the different bars were popping kegs pretty much every night. That was really fun, when you see it sputter. Fortunately, we brought backups to most of the nights, so if they underestimated, we were prepared for it.

Friday night, driving out to the event at The Shepherd & The Knucklehead (in Haledon), we were like "Why did we do five nights in a row of this?" But once you get in and start talking to people about the beer, it wakes you up a little bit.

BSL: And before that, you did a soft opening ...

BO: Andy's (Corner Bar) in Bogota got the beer a week ahead of the launch just because if our truck doesn't work again, we can literally carry the kegs to that place.

BSL: So how did that go?

BO: It was a little nerve-wracking doing that because if people didn't receive it well, we might have undercut our entire launch week. They got 'em and hooked 'em up on a Tuesday night, and by Thursday and Friday they were gone. So it was a good way to start; those initial reactions were positive so it gave us a little more confidence that going into launch week that we'd be doing all right.

BSL: Talk a little about how, with limited resources as they are, you were able to get both beers ready for the launch.

BO: We have the 30-barrel fermenter here. We brewed the Ragin' Bull into that, and then Greg (High Point owner Greg Zaccardi) let us use one of his 15's so that we could launch the two simultaneously.

BSL: And going forward?

BO: They're scheduled to brew the Ragin' Bull again on April 2, so we're rolling.

AM: We'll have bottles available Saturday (March 23rd). It will be our first delivery of bottles.

|

| Carrying the empties into High Point |

BO: Thursay (March 21st) they bottle it. We'll pick it up Saturday ...

AM: There's three or four local beer stores that will get them.

BSL: Let's go back to January for a moment. What was it like for the first brew?

BO: We came up two weeks in a row for the Ragin' Bull first, and then the first brew of the Blackhorn, which they, I think, were really excited about. High Point does a lot of very traditional beers. The American black lager is definitely pushing the envelope for what they're used to here. So it was fun seeing how excited they got helping us brew it.

BSL: As homebrewers, you guys had a wide portfolio, reflecting a lot of creativity. Now with two beers in the market, and the process by which you do things, how do you stir some of that creativity into market presence?

AM: What we're doing is, we're adulterating some of the flagship versions with our one-off type spins that we would normally do. Whereas if we would brew a coffee beer, now we're just doing the Blackhorn with coffee or the Ragin' Bull with hazelnut, or something that's interesting for a specific night, like we did for the launch week. We had a special cask for each of the events that had something unique that we did to it that probably won't be available on a mass scale for a while.

You can't really produce more than your single styles that you're going to launch with in the market, because it's available once every 30 days and you're producing a thousand gallons at a time; it's also a big risk. On the homebrew scale we were able to experiment a lot more, but I think you will see more of that to come.

BSL: As we get closer to warmer weather, do you see any flexibility to accommodate a seasonal, perhaps managing a third beer in there?

BO: I think what's more realistic is, as we expand our capacity – either adding another tank here or looking to expand production elsewhere – you'll see that. If we can get a second tank in here by the end of the summer, then we'll have what will eventually become a flagship, but it's just an easy-drinking sessionable porter that will be more of like a fall/winter seasonal the first time around. Then the fourth flagship is a rye beer, very basic, very easy-drinking, smooth ... The rye gives it a lot of character so that a craft enthusiast can really enjoy it, but the Bud Light drinkers of the world could pick it up and just crush through it on a warm summer day.

You might see those introduced this fall and this spring, but it's going to depend on the demand of the initial two. We're not going to introduce new beers if we can't keep up with the production of the first two we have.

|

| Bolero Snort sixtels |

BSL: Even before your launch, you guys had a little bit of a fan following as homebrewers; there was some chatter about Bolero Snort. To now be able to answer that with beers in the market now, talk a little about that feeling, that satisfaction.

BO: I don't know if the full reality has set in, a least for me. I guess it's fun, although not much fun having to pay for our beers when we walk into a bar (laughs). But, you know, it was a long time coming. We had illusions very early on as to how long it would take. Once we really sat down and hammered out a plan, we got our federal approval in a week and a half last January (2012), got our state stuff (turned) in the beginning of March, and that just languished on and on and on.

We got it in in March, and we're like, OK, three, maybe six months, end of the summer, beginning of the fall at the latest. It took until Dec. 17th to get licensed.

BSL: And you're licensed as a beer company, a distributor?

BO: The way it works in this state is, to contract brew you're licensed as a distributor. But the only beer we're distributing is ours. Our beer is brewed exclusively for us.

BSL: The same thing as Boaks, also brewed here at High Point, and Beach Haus (brewed by Genesee) ...

BO: For us, contracting was just kind of a way to grow that following we started as homebrewers, establish the brand in the market, build the name a little bit, and then hopefully at the end of this year start raising capital, and then hopefully January, February, spring at the latest, we'll settle on a permanent home and start building it out. I think, realistically, by the end of next year, you'll see beers coming out of our own facility.

And that's when you'll get to see us flex our brewing muscles. Our normal brewhouse will definitely have a pilot system in there. Those (recent) law changes in the state, that was really important for us in staying here. We could do those 1-barrel batches, put them on tap in the tasting room and see how they do, and use that as a way to gauge what we're going to scale up as either the next seasonal or full production batch.

BSL: In terms of development, brand and actually brewery, how does the rest of calendar year 2013 shape up?

|

| Ready for bottling |

BO: Phase One was get the beer out. We finally accomplished that after a long, drawn-out paperwork process. Phase Two will be growing on a contracting level, either expanding here or looking to one of the bigger contracting sites for the flagship brands. While we're doing that, we'll hammer out the business plan for the next stage of things ... end of the summer, September, October start to raise the capital to take the next step.

I think establishing the brand – it's only something that's kind of recently come to us, we'll have an established brand – we'll be able to scout out a couple of potential locations and almost shop the brand, say "Hey, this is a growing industry; us being here is going to help the rest of the town, create some jobs, people are going to be able to hang out at the tasting room, then go to the restaurants or the shops. I'm hoping that being an established brand will help us on that front, so we don't deal with some of the hang-ups that other people (experienced) when they were trying to find their permanent home.

AM: Not to say that there won't be, though.

BO: I'm sure there will. I'm knocking on wood (laughs).

BSL: Talk a little bit about the beers, the origins of them ... how did they come about?

AM: Blackhorn was the first one we had our mind set on. Originally, Bob had a regular pale IPA. We were out having a couple of beers one night, and we were like, "You know what? This black IPA style is really emerging; nobody's really doing it. There's a couple of them out there ... I really like dark beers. I think it has a promising future, so let's take that route. Let's be one of the pioneers, with an American-style black lager, or black ale (though) it turned out to be a lager. And it went from there.

BO: Even launching with two as a contracting brewery ... you see the Bronx guys over in New York have their one flagship. Juggling the two between the one tank right now is tough. Usually you see a normal flagship portfolio with something on the amber kind of side, something hoppy and something dark. We thought we could combine those (latter) two and go with the something light and expand from there.

BSL: You ended up using the High Point house yeast, which unlike a lot of places, is a lager yeast. But these two beers started out as ales, right?

AM:

AM: They started out as ales. We tested the recipes multiple times with a lager yeast. It tasted better. It tasted cleaner, and you know what? We trust the work they're doing here, that the beers are going to come out solid. I don't think that by (substituting) a lager yeast is taking away from any of the quality that this beer should be. I think it's totally open for interpretation. There's no such thing as a defined style, that this beer should be this ...

When people see that it's a lager, they're like, "Wow, I didn't know it's a lager, and I didn't know a lager could taste so good."

BSL: A lager can be more difficult to produce ...

AM: It's hard to do a lager, and I think if anybody's going to do good lager, it's going to be this brewery.

BSL: When you get the chance to bring them in-house, will they continue to be lagers?

BO:

BO: I think you're not going to see these beers change. We're not going to change just because we're changing our house yeast. Having our own place and the plans for it, I wouldn't be surprised to have two or maybe three different (yeast) strains going at any given time, depending on how the portfolio of beers expands.

BSL: Your distribution is limited for now to North Jersey, for a clear reason. What are the prospects for widening it?

AM: This is the whole company, just us two. Deliveries are on top of our full-time jobs. We can't really go out that far, especially to try to keep a supply on for southern or more central locations because the deliveries are what take the most time. So our focus is mostly on North Jersey right now, with the capacity that we have.

BO: We don't have enough beer to go down south right now. Once we get some added capacity, we'll start to broaden our range. It's terrible from a delivery standpoint, but we really kind of cherry-picked which areas we wanted to be in up here. It sucks to be driving 15 or 20 (minutes) or a half hour between our different accounts right now. But we didn't want to have three acounts in one spot and three accounts in another and then be done.

Now that we have bottles, we're trying to find a bottle shop close to each draft account. We model a lot of the business about how we were as consumers, especially in New Jersey, you drink in a bar – I go buy a six-pack and drink at home if it's something I like. So we wanted to make sure that places where it's doing well on draft people always have a place to go and pick it up.

AM: As time progresses, I think you'll see more Bolero beers at varying locations. Our aim, of course, is to be south and to be everywhere. But right now, it's just not really realistic with the amount that we're producing. We really have a tight, tight limit as to how much we can make, so North Jersey right now is really what works for us.

|

| Bolero Snort fermenter at High Point |

BSL: It's nice to have a buzz about your name, but sometimes the back side to that is when you want to be able to grow you may have to stay within your constraints a little while longer.

BO: I think you'll see us down south before you see us hopping into another state. If we can grow the business and just continue to be closer and closer together in our accounts, I'd be happy never selling a drop outside this state. At least for the foreseeable future, we'll just be in Jersey, and we'll worry about getting broad coverage of the state before we go dealing with anymore paperwork ...

BSL: But you're still going to tease the beer at the Atlantic City beer festival (April 5-6)?

BO: Well, we figure that, if nothing else, it's a way of getting (the beer) down south for one event, get people excited ... Anywhere between 24,000 and 30,000 people show up for that ... people are coming from all over the state, other states as well.